blogCustomer Spotlight: 3D Printing Corporation

3D Printing Corporation is a startup using 3D printing to tackle the next generation of supply chain infrastructure and fundamentally change manufacturing. In this challenge, CTO Yoichiro Koga actively uses Amplified as a partner in his job leading R&D and IP strategy.

As a child Yoichiro was passionate about developing video games. From this experience, he noticed the impact that the "unbreakable rules" of the game had on the player's behavior and realized the importance of creating those rules. Now he is using 3D printing technology as a basis to reimagine supply chain business models and write a new set of “unbreakable rules”. We talked with him about the R&D driving this innovative new service and how he integrates Amplified in those activities to build a patent network supporting their revolutionary new business model.

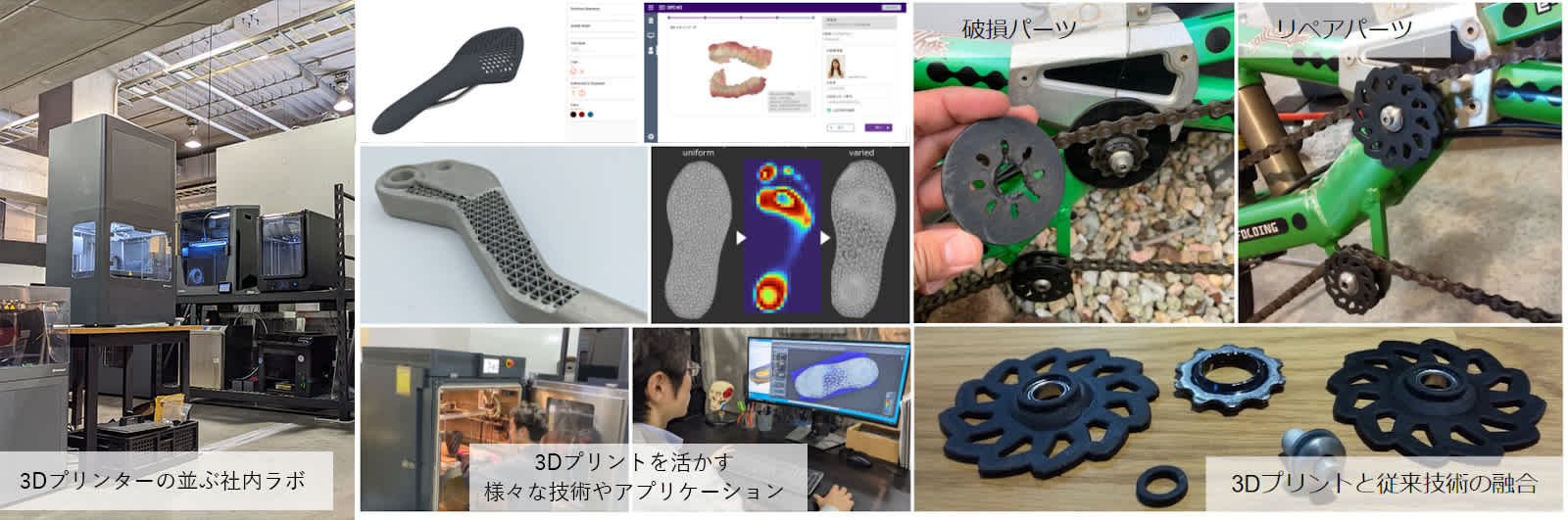

When customers want to implement 3D printing technology there are some gaps that prevent them from making the transition. I understand that 3D Printing Corporation offers a service that fills these gaps?Yes, our business has three main pillars. First, consulting on the introduction of 3D printers to their business. We advise customers on the right hardware, whether to buy or lease, and if our factory facilities are sufficient we may lend them our manufacturing capacity in order to build parts.

The second is a design business for additive manufacturing called DFAM (Design for Additive Manufacturing). Simply put, it's data design support for 3D printing. A 3D printer is basically a system that creates things from data, so you need the correct data to take full advantage of it. We help our customers convert what they want to make into 3D data, realize higher throughput, and more. In some cases, we do not simply pass the data, but also complete materialization and provide manufactured parts.

The third is a new business we started last November, which is a digital platform that provides one-stop 3D printing manufacturing technology. When the user inputs design data to the platform, it automatically points out where there are high possibilities of data deficiencies or manufacturing failures, corrects the data, then manufactures and delivers the parts.

Conventional manufacturing technology made from "molds" is difficult for small volumes and this constrains the manufacturing side. With 3D printing you support even just a single part. By the end of the year, we expect to reach a manufacturing speed of several thousand parts a month and we plan to expand our factory so that we can eventually handle 1 million parts a month. From one part to millions of parts, this flexibility of scale is only possible through 3D printing technology.

Product development that leverages 3D printing technology possesses incredible potential to invent a new thing because the technology can realize product design and manufacturing processes that are free from the constraints of traditional manufacturing.

For example, one of our customers contacted us about improving a part used in a consumer product. Their problem was that the conventional manufacturing method had no choice but to combine metal materials which resulted in non-recyclable parts. We asked them why not design using a completely different mechanism from the beginning so that you can manufacture with a single material? They were shocked when we showed them a new design that would work thanks to 3D printing and we also decided to patent the idea.

3D printing has completely different methods and rules from conventional manufacturing, so the criteria for what is good, what costs, and what doesn’t are totally different. In light of the rules of 3D printing technology, instead of thinking about reproducing the same structure you can think about how to 3D print the desired function and end up with something completely different that works well. It's easy to create innovative products like this with 3D printing technology and patenting those ideas is just a step away.

We’ve also used 3D printing to manufacture toothbrushes. All the toothbrushes on the shelves have basically the same shapes, but the shape of our 3D printed toothbrushes was completely different. That's because we used the new rules of 3D printing for manufacturing to focus on the "purpose" and "function" of brushing and cleaning the teeth instead of the form.

It's quite an interesting experience because it feels like going back to the beginning of history and thinking about how to make things from scratch for the very first time.

It is fascinating hear the rules of 3D printing cause familiar things to be reborn in a completely new shape. When you’re turning those ideas into patents, how does Amplified fit in?First of all, we use Amplified to search for similar patents when patenting new products and ideas made possible by 3D printing technology, such as the examples I just mentioned. In my case, I come up with new ideas reflexively, so I don’t mean to say that I’ll dream up a new idea by referring to existing patents. But to verify that something close to our idea doesn’t already exist we need to check similar patents using Amplified.

While writing many of my own research papers, I’ve gotten used to predicting what kind of new research will be published in this field so with patent searching as well I can usually guess what kind of a patents a product probably has and focus in on those with specific keywords. Then I quickly look over the resulting patents to get a sense of the surrounding area. If there’s nothing similar even after filtering with specific keywords I sometimes change directions and then if I still can’t find anything I’m satisfied the job is done. It’s amazing how quick that process is. In terms of actual total time spent, it’s no more than a few hours and for shorter cases I’m done after tens of minutes.

On the other hand, when there are many similar patents, it takes about 1 to 2 hours to find them all. After that, it’s tens of minutes to pick which have the highest similarity out of all the similar patents and another few hours to properly identify the key points of novelty. Even in those cases it’s up to 8 hours of work. Finished within a day.

We also use Amplified to see patent trends by industry. For example, if you look into the toothbrush industry, you'll find that many patents are filed for how to stand a brush, for a cross section of a brush, and for a handle. From this we can see what kind of differentiation points the industry pays attention to based on the conventional way of thinking and then decide our patent policy in light of understanding those trends. Rather than simply searching for similar patents, we consider the technology trends when searching.

Why did you decide to introduce Amplified to your organization?I heard about Amplified from a trusted friend and thought it sounded interesting so I tried it. At the time, I was planning to apply for more than two patents a month, so I compared the cost of asking a patent law firm to do the search against doing it myself with Amplified and found that as long as I’m filing at least two patents per month it is cheaper to use Amplified.

But that's just a comparison of "cost"; the most remarkable difference is "speed". It takes 10 business days to request a similar patent search from a patent office. After 2 weeks they usually get two or three similar patents saying we have to make sure to avoid those. However, since I can see the end goal to some extent, my idea was to shorten the time to filing as much as possible and instead of trying to confirm whether similar patents exist or not, focus on confirming that no similar patents exist. It would be really frustrating if another company happened to beat us to filing by just two weeks difference.

In addition, my aim is to always be thinking “two steps ahead” when getting patents and I need Amplified’s speed to realize that. In our newly launched digital platform business, we actually filed a considerable number of patents before the official product release. As we gradually release new features we are also preparing to lock down related patents before the release date. There are probably some people who can look at our service and imagine what kind of other related features may come so we aim to protect peripheral technologies as well before publication of the core feature. There are dozens of patents covering each of the key parts of the service. I think this is how to get a product with strong rights that are difficult to breach like Apple's iPhone.

Of course, at the same time as protecting our own technology, we also want to increase the number of patents that generate profits through external licensing royalties. That’s a game of numbers to some extent and the raw speed of Amplified supports that as well. When I decided to introduce Amplified, I didn't search for other software. I was so impressed with Amplified that I felt looking for other solutions wouldn’t be worth the effort. Even if something else similar existed, I didn’t see the point in looking further given how happy I was with the service.

What are your plans for the future of your business?We’re putting our effort into using 3D printing to provide a digital platform that democratizes quality manufacturing and enables a new supply chain structure.

We are driving towards a future that’s a lot like what Amazon did for retail where customers anywhere in the world can get what they need even if it’s just a volume of one. Working towards that purpose, we want Amplified as our partner in IP to continue delivering the same speed and value.